Understanding Failure. Preventing Recurrence.

Comprehensive failure analysis services to safeguard your operations.

We help industries decode failures and improve reliability through detailed forensic investigation.

Request Analysis Learn Our ServicesIndustrial Failures Analysis and Prevention

Join our comprehensive short course on industrial failure analysis techniques and prevention strategies.

Learn from industry experts with decades of experience in failure analysis and prevention.

Register NowMetallography and Fractography in Failure Investigations

Master the techniques of metallography and fractography for failure analysis and quality assessment.

Hands-on training with state-of-the-art equipment and real-world case studies.

Register NowNew Equipment Acquisition

NCFA has purchased a state-of-the-art portable XRF analyzer for on-site material analysis

OES GNR Equipment Arrival

Our new OES GNR metal analyzer has arrived, enhancing our material characterization capabilities

Olympus Microscope Acquisition

We've added a high-resolution Olympus microscope to our failure analysis laboratory

New Equipment Acquisition

NCFA has purchased a state-of-the-art portable XRF analyzer for on-site material analysis

OES GNR Equipment Arrival

Our new OES GNR metal analyzer has arrived, enhancing our material characterization capabilities

Olympus Microscope Acquisition

We've added a high-resolution Olympus microscope to our failure analysis laboratory

Our Services

Root Cause Failure Analysis (RCFA)

A systematic process of identifying the factors that caused a failure and the actions that can be taken to prevent or mitigate future failures.

Replica Metallography

A non-destructive technique of obtaining the microstructure of a metal or alloy without damaging the original specimen.

Corrosion Damage Assessment

A comprehensive evaluation of the extent and severity of corrosion damage on a material or structure.

Reverse Engineering

A process of analyzing the design and functionality of a product or system by taking it apart and examining its components.

Ftiness for Service & Remaining Life Assessment (RLA)

A method of estimating the remaining useful life of a component or system based on its current condition, operating history, and expected future conditions.

Fatigue Life Estimation

A technique of predicting the number of cycles or hours that a component or system can withstand before it fails due to fatigue.

Testing Services

At the National Center for Failure Analysis, we offer a comprehensive range of testing services utilizing state-of-the-art equipment. Our advanced instrumentation allows us to perform detailed material characterization, mechanical testing, and failure analysis to support industries across various sectors.

Below is a list of our available testing equipment and their primary applications:

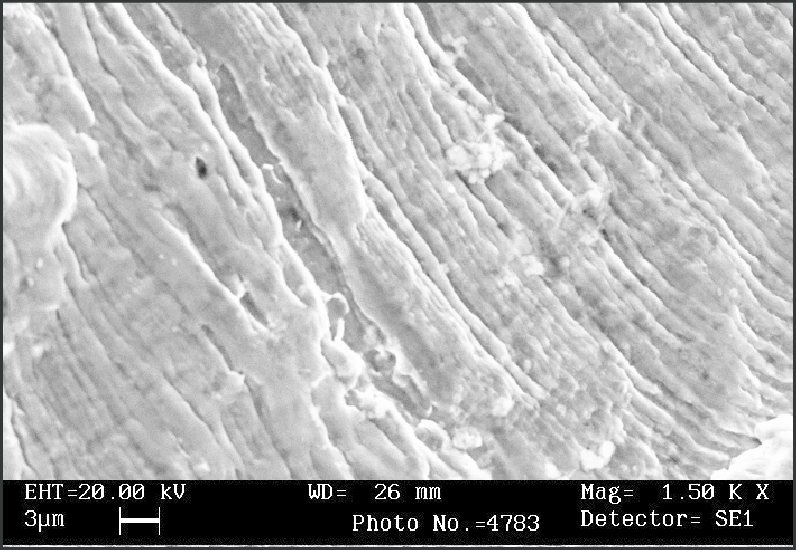

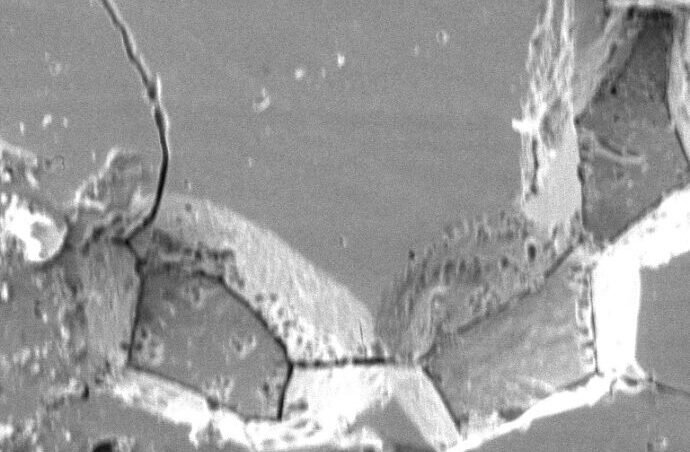

Scanning Electron Microscope (SEM+EDX)

High-resolution imaging and elemental analysis of surfaces. Used for detailed examination of microstructures, fracture surfaces, and material composition.

Portable X-ray Fluorescence (XRF)

Non-destructive elemental analysis of solids on-site. Determines material composition and identifies alloy grades.

Optical Emission Spectrometry (OES)

Precise elemental analysis of metals. Used for quality control, material verification, and certification.

MIC Corrosion (Microbiologically Influenced Corrosion)

Caused by microorganisms such as bacteria. Common in pipelines, storage tanks, marine structures, and cooling systems. Leads to localized attack like pitting, crevice corrosion, and under-deposit corrosion.

Hardness Testing

Measures material resistance to deformation. Assesses heat treatment effectiveness and material strength properties.

Impact Testing

Determines material toughness and resistance to fracture under high-rate loading conditions.

Fourier Transform Infrared (FTIR) Spectroscopy

Identifies organic compounds and functional groups. Used for polymer analysis, contamination identification, and material characterization.

Phase Analysis

Identifies crystalline phases and determines crystal structure of materials.

Carbon Sulfur Analyzer

This equipment tell carbon and sulfur of materials very accuratly.

Creep Testing

Determines material behavior under constant load at high temperature. Predicts long-term strength and life of components. Assists in remaining life assessment of critical parts.Helps in selecting materials for high-temperature applications.

Wire cutting Machine

Achieves high precision and complex shapes in hard materials.Provides smooth surface finish with minimal need for further machining.Cuts without inducing stress or distortion in the workpiece.

Universal Testing Machine (UTM)

Mechanical testing of materials under tension, compression, bending, and shear to determine strength and deformation properties.

Micro Hardness Testing

Achieves high precision and complex shapes in hard materials. Provides smooth surface finish with minimal need for further machining. Cuts without inducing stress or distortion in the workpiece.

Ultrasonic Flaw Detector

Detects internal flaws without damaging the material. Provides accurate depth and size measurement of defects. Portable, fast, and applicable to a wide range of materials.

Ultrasonic Thickness measurement

Measures wall thickness without cutting or damaging the part. Detects thinning due to corrosion or erosion. Fast, portable, and accurate for in-service inspection.

Profilometer

Measures surface topography, roughness, and step heights with high precision.

Paddle testing (pickle ball testing)

Ensures paddles meet official performance standards. Checks deflection, durability, and surface properties for fair play. Improves player safety and product quality control.

Electromagnetic compatibility Testing (EMC Testing)

Ensures devices do not interfere with other electronics.Confirms compliance with international regulations/standards. Improves product safety, reliability, and market acceptance.

Coefficient of Friction Testing

Determines slip or grip behavior between surfaces.Helps in material selection and design safety.Ensures quality control and performance consistency.

Grinding/Polishing, Etching & Optical Microscopy

Sample preparation and examination of microstructures for metallurgical analysis and failure investigation.

Metacut

Precision sectioning of metallurgical samples for analysis with minimal deformation.

Vicker Hardness Tester

Measures material hardness using a diamond indenter with a square-based pyramidal shape.

Thermogravimetric Analysis (TGA)

Measures changes in material weight as a function of temperature in controlled atmosphere.

Differential Scanning Calorimetry (DSC)

Measures heat flow associated with material transitions as a function of temperature and time.

Micro-Vicker Hardness Tester

Measures hardness of small areas, thin materials, or individual microstructural constituents.

LEEB Hardness Tester

Portable hardness testing using the dynamic Leeb rebound method for large or installed components.

Why Choose NCFA

Experience

Years of specialized analysis with certified protocols and procedures.

Expertise

Team of highly qualified metallurgists and materials engineers.

Facilities

State-of-the-art SEM labs, OES equipment, and hardness testers.

Quality

Accredited, ISO-compliant with traceable chain of custody.

Annual Training Program - CY 2025

Corrosion Failures in Industry

Understand corrosion failures through case studies.

Reverse Engineering

Hands-on exposure to reverse engineering.

Industrial Failures - Analysis & Prevention

Explore industrial failures & prevention strategies.

Metallography & Fractography in Failure Investigations

Advanced metallography & fractography for investigations.

Industries We Serve

Automotive

Aerospace

Manufacturing

Infrastructure

Energy

Oil & Gas

Fertilizer Plants

Refineries

Cement Plants

Textile Industry

The Team

Dr Anjum Tauqir

Dr Anjum Tauqir did his masters in metallurgical engineering from Moscow Institute of Steel and Alloys and PhD from University of Connecticut. He has more than 30 years of experience in energy beams-materials interaction, development of hi-purity aerospace alloys and failure analysis.

Contact: +92 051 907 5678

Email: ncfa@ist.edu.pk

Dr Syed Wilayat Husain

Dr Syed Wilayat Husain did his BS in Metallurgical Engineering from Dawood College, Karachi. He got his MS and PhD in Metallurgy from the University of Connecticut, USA. He has more than 30 years of experience in Alloy Development, Materials Characterization and Failure Analysis.

Engr Waseem Arshad

Engr Waseem Arshad got his Masters in Mechanical Engineering from SMME NUST and Bachelors in Materials Engineering from SCME NUST. He has been involved in various industrial projects.

Contact: +92 051 907 5734

Email: ncfa@ist.edu.pk

Engr Obaid Ur Rauf

Engr Obaid Ur Rauf did his Bachelors and Masters degree in Materials Science & Engineering from Institute of Space Technology (IST), Islamabad and has specialized in Metals & Alloys.

Contact: +92 051 907 5734

Email: ncfa@ist.edu.pk

Engr Umer Rasheed

Engr Umer Rasheed serves as a Graduate Trainee Engineer at NCFA, holding a BS in Materials Science and Engineering from the Institute of Space Technology, Islamabad.

Engr Mirza Qasim Shehzad

Engr. Mirza Qasim Shehzad completed his bachelors degree in Materials Science & Engineering from Institute of Space Technology, Islamabad.

Case Studies

Fatigue Failure in Rotating Shafts

Problem: Premature failure of rotating shafts in manufacturing equipment.

Investigation: Fractography and material analysis revealed stress concentration points.

Corrosion-Induced Cracking in Heat Exchanger

Problem: Repeated cracking in industrial heat exchanger components.

Investigation: Chemical analysis and microscopic examination identified corrosive agents.

Wear Failure in Hydraulic Components

Problem: Excessive wear in hydraulic system components leading to frequent replacements.

Investigation: Surface analysis and hardness testing revealed material inconsistencies.

Pipeline Fracture in Oil Refinery

Problem: Catastrophic fracture in a high-pressure pipeline at an oil refinery.

Investigation: Material testing and stress analysis to determine failure mechanism.

MIC Corrosion in Oil Pipeline

Problem: Rapid corrosion and pitting in offshore oil pipelines.

Investigation: Microbiological analysis and corrosion product examination.

High Temperature Hydrogen Attack (HTHA)

Problem: Component degradation in high-temperature hydrogen service.

Investigation: Microstructural analysis and damage mechanism evaluation.

Careers at NCFA

Join our team of experts dedicated to solving complex engineering challenges through failure analysis. We offer exciting opportunities for professional growth in a research-oriented environment.

Current Openings

Office Clerk / Administrative Assistant

We are seeking a highly organized and detail-oriented Office Clerk to join our administrative team. The ideal candidate will have excellent communication skills and proficiency in office software.

Responsibilities:

- Manage front desk operations, including greeting visitors and answering phone calls

- Maintain and organize physical and digital filing systems

- Handle incoming and outgoing correspondence, including mail and email

- Assist in preparing reports, presentations, and documents

- Schedule appointments and maintain calendars for staff members

- Coordinate meetings and conferences, including logistics and materials preparation

- Manage office supplies inventory and place orders when necessary

- Assist in basic bookkeeping tasks and expense reporting

- Provide administrative support to various departments as needed

- Ensure office equipment is properly maintained and serviced

- Handle confidential documents with discretion and integrity

Qualifications:

- Proven experience as an office clerk, administrative assistant, or relevant role

- Proficiency in MS Office (MS Excel, MS Word, and MS PowerPoint in particular)

- Excellent time management skills and ability to prioritize work

- Attention to detail and problem-solving skills

- Strong organizational skills with the ability to multi-task

- Excellent written and verbal communication skills

- High school diploma or equivalent; Bachelor's degree preferred

Request Analysis

Contact Information

ncfa@ist.edu.pk

ist.ncfa@gmail.com

Phone

051-9075417

Fax

051-9075539

Address

National Center For Failure Analysis

Institute of Space Technology

1, Islamabad Highway, Near CDA Toll Plaza,

Islamabad 44000, Pakistan